OSH Answers Fact Sheets

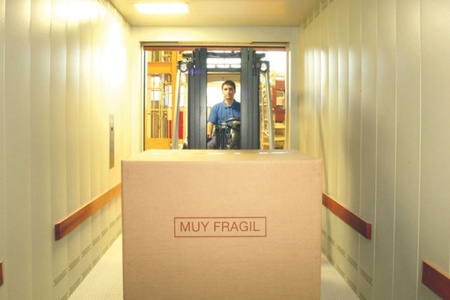

. If using a service elevator with a PIT, the operator must: verify that the elevator capacity can support the weight of the lift truck plus the load; confirm that the dimensions of the elevator (width and height) are sufficient to accommodate the PIT and load; approach the elevator slowly and stop at a safe distance before. Our full fleet of forklifts, cranes and hoists provide ample strength, lift height, versatility, and the performance features needed for most applications. From reach forklifts to warehouse forklifts or rough terrain lifts – you can rely on our top-tier material handling equipment. Whether you need to move or lift material - on solid ground or mud, rocks, hillsides, and other rough terrain.

Easy-to-read, question-and-answer fact sheets covering a wide range of workplace health and safety topics, from hazards to diseases to ergonomics to workplace promotion. MORE ABOUT>

Download the free OSH Answers app

- 2016 CAT Lift Trucks GP25N (3 valve), These GP15N/GP35N heart-of-the-line forklifts will move 10,400 more loads per year than the leading competition. Forklift Services Of Oregon - Website Portland, OR.

- A forklift has its own height, the height of its boxes, and the height of its lift, all of which could be too high and catch in a door frame or other overhanging item. If the item is stronger and heavier than your forklift, you could be sent flipping over backwards.

What vehicles can you load and unload using forklift trucks?

Forklift trucks provide (secure) the efficient loading and unloading of straight trucks, tractor trailers, railway cars and elevators.

How should you prepare the work area for using a forklift truck for loading/unloading operation?

- Set the vehicle's brakes up.

- Chock the vehicles' wheels.

- Install fixed jacks to support a semi-trailer that is not coupled to a tractor to prevent it from upending.

- Post signs warning not to move the vehicle.

- Check that the height of the vehicle's entrance door clears the forklift height by at least 5 cm (2 in.).

- Make sure floors can support the combined weight of the forklift and the load.

- Inspect interior of a vehicle for the following: trash, loose objects and obstructions; holes or weak floors; poor lighting; and low overhead clearance.

- Install anti-slipping material in any area that could be a hazard because of weather conditions.

- Ensure that docks and dock plates are clear of obstructions and not oily or wet.

- Protect gaps and drop-offs at loading docks.

- Use dock levelers.

What should you do to load (unload) vehicles using a forklift truck?

- Keep forks pointed downhill when traveling without a load on a ramp.

- Keep forks pointed uphill when traveling with a load on a ramp.

- Stay clear of edges of docks, rail cars or ramps. Have edges clearly marked.

- Do not tow or push railway cars or trucks with a forklift.

- Do not operate forklifts inside vehicles for long periods without ventilation.

- Make sure that the dock plate is properly secured and can support the load before driving over it. (Load weight should be clearly marked.)

- Drive carefully and slowly over the plate. Do not spin wheels.

When loading railway cars, what is important to know?

- Cross railway track on a diagonal.

- Set handbrakes, wheel blocks and derailer before entering a railway car.

- Do not park a forklift within three meters of railway tracks.

- Do not open railway car doors with forklift forks.

What should I do when using a forklift truck in an elevator?

- Do not use a forklift truck in any elevator unless specifically authorized to do so.

- Before entering any elevator, make sure that the elevator is designed to carry a forklift, considering factors such as clearances, ventilation, and weight capacity (make sure weight of the forklift plus load weight does not exceed the elevator capacity).

- Approach the elevator slowly, stop at a safe distance from the elevator gate and enter squarely.

- Neutralize the forklift controls, shut off the motor, and apply the brakes.

Add a badge to your website or intranet so your workers can quickly find answers to their health and safety questions.

What's New

Check out our What’s New listing to see what has been added or revised.

Need more help?

Contact our Safety InfoLine

905-572-2981

Toll free 1-800-668-4284

(in Canada and the United States)

Tell us what you think

How can we make our services more useful for you? Contact us to let us know.

Disclaimer

Although every effort is made to ensure the accuracy, currency and completeness of the information, CCOHS does not guarantee, warrant, represent or undertake that the information provided is correct, accurate or current. CCOHS is not liable for any loss, claim, or demand arising directly or indirectly from any use or reliance upon the information.

Elevator Loading Requirements

Every elevating device has a loading classification pertaining to the capacity of the elevating device and to the nature of the loading method. It is important that the loading classification matches the intended use of the elevating device in order to ensure safe operation. The following is a description of the loading classifications permitted under the B44 Elevator Code and that are available from Delta Elevator Co Ltd.

Please be advised that standard elevator systems are designed for Class A loading. All other types of loading are more rigorous. The only safe practice where the class of loading is not absolutely known is to treat the elevator as if it were specifically designated for Class A loading. Any other practice could be dangerous for the elevator equipment and unsafe for the passengers and/or cargo.

Class A Loading

Most passenger elevator systems and standard freight elevators are designed as Class A, or “General Freight Loading”. The actual amount of a one-piece load being moved on to or off of the elevator cannot exceed 25% of the stated capacity of the elevator system. For example, although the capacity of the elevator may be 2,000 lbs (907 kg), the actual limit of a one-piece load is 500 lbs (226.75 kg). As well, the loading or unloading of the elevator is restricted to manual means or to a hand truck. In the event that a hand truck is used the weight of the equipment must be included as part of the 25% loading restriction.

Class B Loading

Homemade Forklift Plans

This class pertains to freight elevators that are intended for the transport of motor vehicles only, up to the stated capacity of the elevator system.

Class C Loading

NOTE: Class C loading is not permitted for accessibility lifts or for LULA elevators.

Class C1 Loading

This class allows industrial truck loading or unloading of the elevator system. The combined weight of the industrial truck and the load cannot exceed the stated capacity of the elevator. The loading device can remain on the elevator during operation.

Electric Forklift Elevator

Class C2 Loading

This class allows for the loading of the platform at 150% of the stated capacity of the elevator. In most cases, this allows for a one-piece load that equals the capacity of the elevator to be loaded with a forklift or motorized lift truck on to the platform of the elevator. The loading device must be removed prior to the operation of the elevator.

Class C3 Loading

Forklift Elevator

This class allows for heavy concentration loading where the static load during loading and unloading does not exceed the rated load. The combined weight of the load and equipment must not exceed the stated capacity of the elevator system. In practice, Class C3 elevators are most often designated to support single piece loads equal to the capacity of the elevator.

About Delta

Delta is pleased to offer information related to loading class requirements / determination to architects, designers and building constructors at the project design stage.

Delta has a complete Engineering Department and manufacturing facility to meet the specific requirements of custom projects.